CERAMIC PRESS FILTER

Our company INDUSTRIAL MINERALS has launched a new item of Cerafil Filters we have been quiet successful with our launching, the key to this result is a perfect blend of efficiency & effectiveness of our product with a shine of economy range.

Manufactured from high grade Alumina based refractories

- Are made under high pressure & are dense.

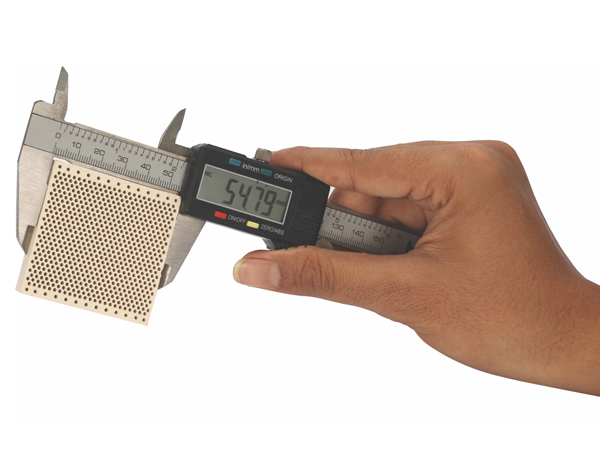

- Are dimensionally accurate

Posses uniform pores and distribution.

The demand for consistent quality castings with lowest levels of inclusions have made conventional gating systems filter dependant. The variety and abundance of filter types are making choice difficult for the foundry man. Most of them are efficient and effective in keeping dirt away, but they are quite expensive. Ceramic filters are used to remove impurities from metals. Because ceramic filters can withstand extremely high temperatures, their use in foundry and investment casting processes continues to be essential.

Ceramic Filters are :

- Specially made for foundry

- Totally indigenous

- Cost effective

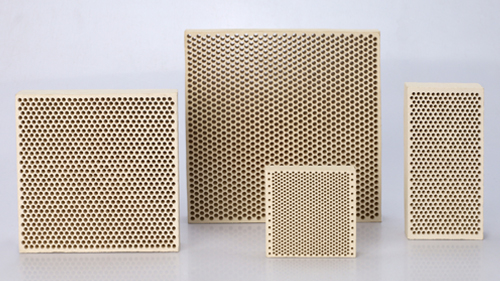

- Different shape & size & width

- Dimensional accuracy

Our Cerafil filters can deliver to temperature as high as 1450°C. Since made from selected quality ceramic and refractory material having good resistance to abrasion and erosion against liquid material.

- Advantages of Metal Filteration :

- Dross/ Inclusion Reduction.

- Improved Machinability/Lower machining Costs.

- Improved Surface finish.

- Improved Productivity

- Good Filteration Efficiency

- Good Consistency

- Consequently Capacity

- Good Dimensional Stability

- Following are the departments on that we have categorized our premises:

- Manufacturing

- Quality controlling

- Warehousing & packaging

- Administrative